The robot application editing system (RAE) is independently developed by our company. Currently, it can control five robots—ABB, Fanuc, Toshiba, Yaskawa, and Kuka—and comes with exclusive control software so that users who do not know how to write programs can also easily operate.

The following are the advantages of this system:

⭐The graphical interface of the software is simple, time-saving, and easy to understand.

⭐System application has various functions and quicker outcome production.

⭐I/O listing and user guide, convenient management, faster problem solving.

⭐System I/O module expansion, eight sets of GPIO, economical price.

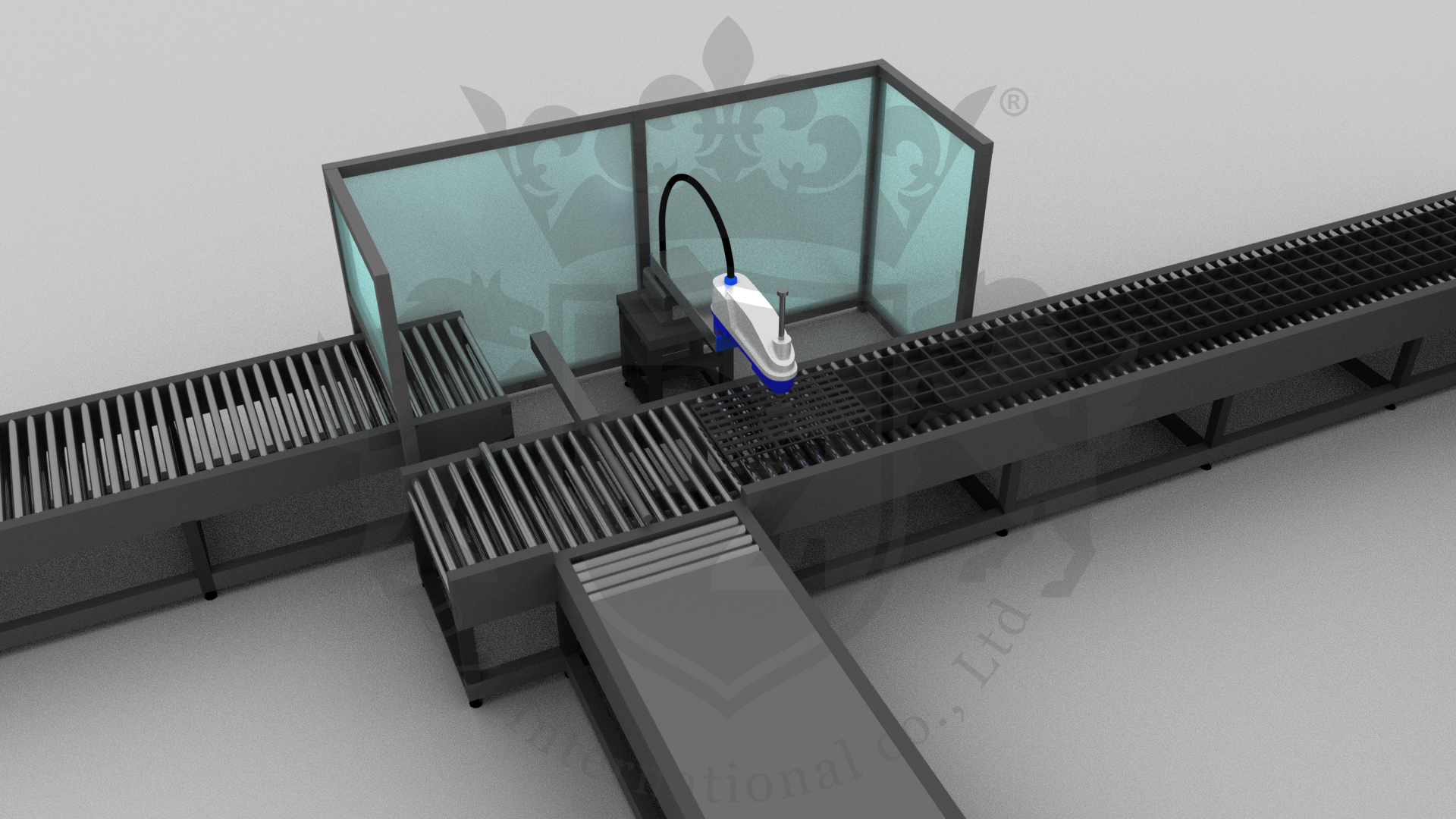

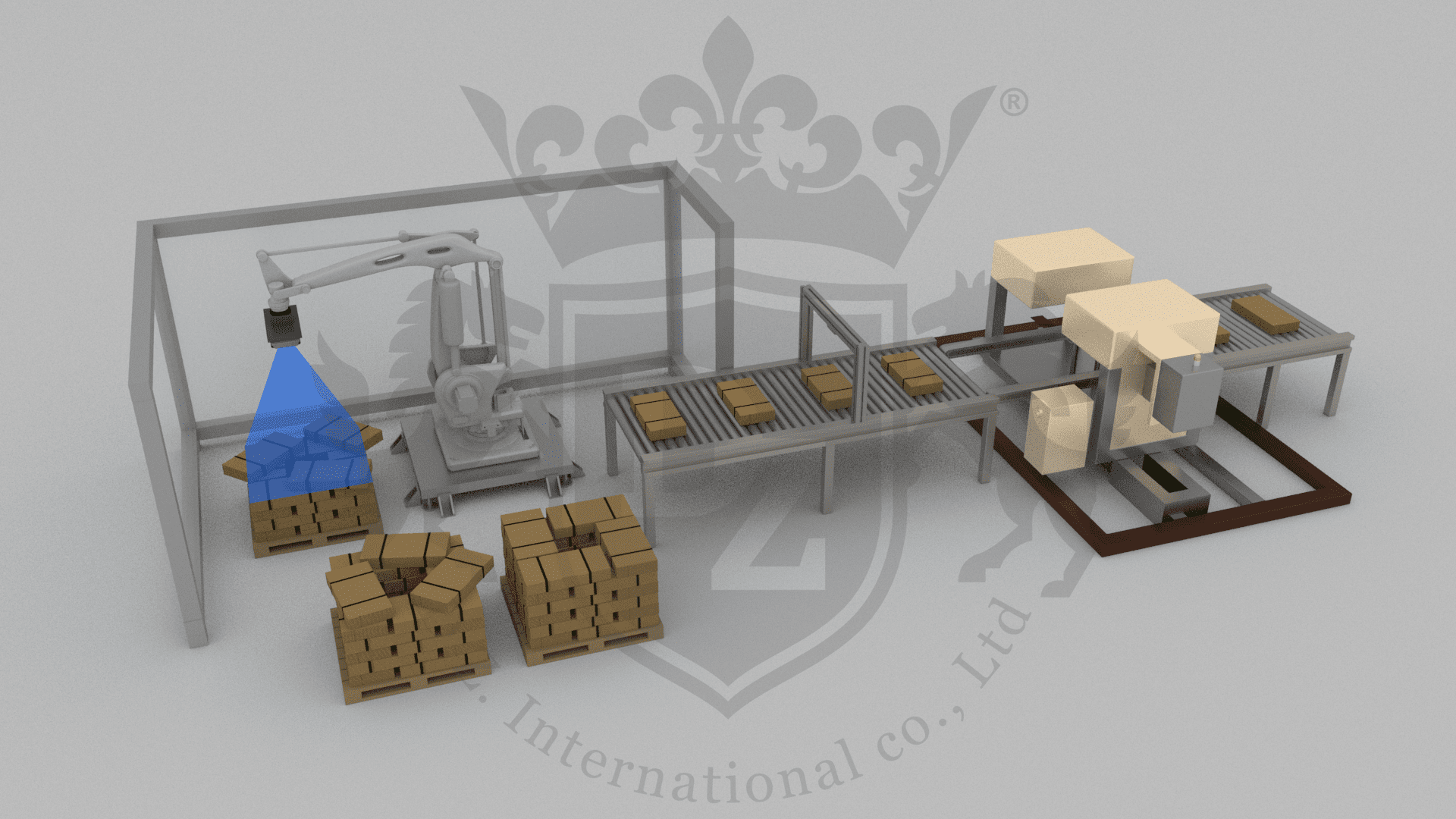

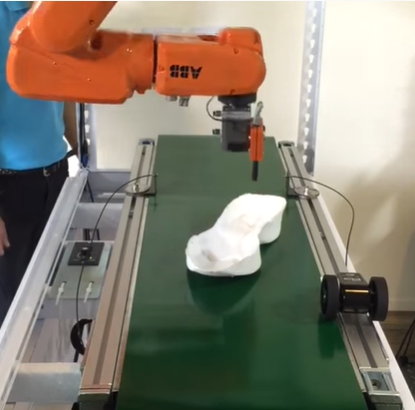

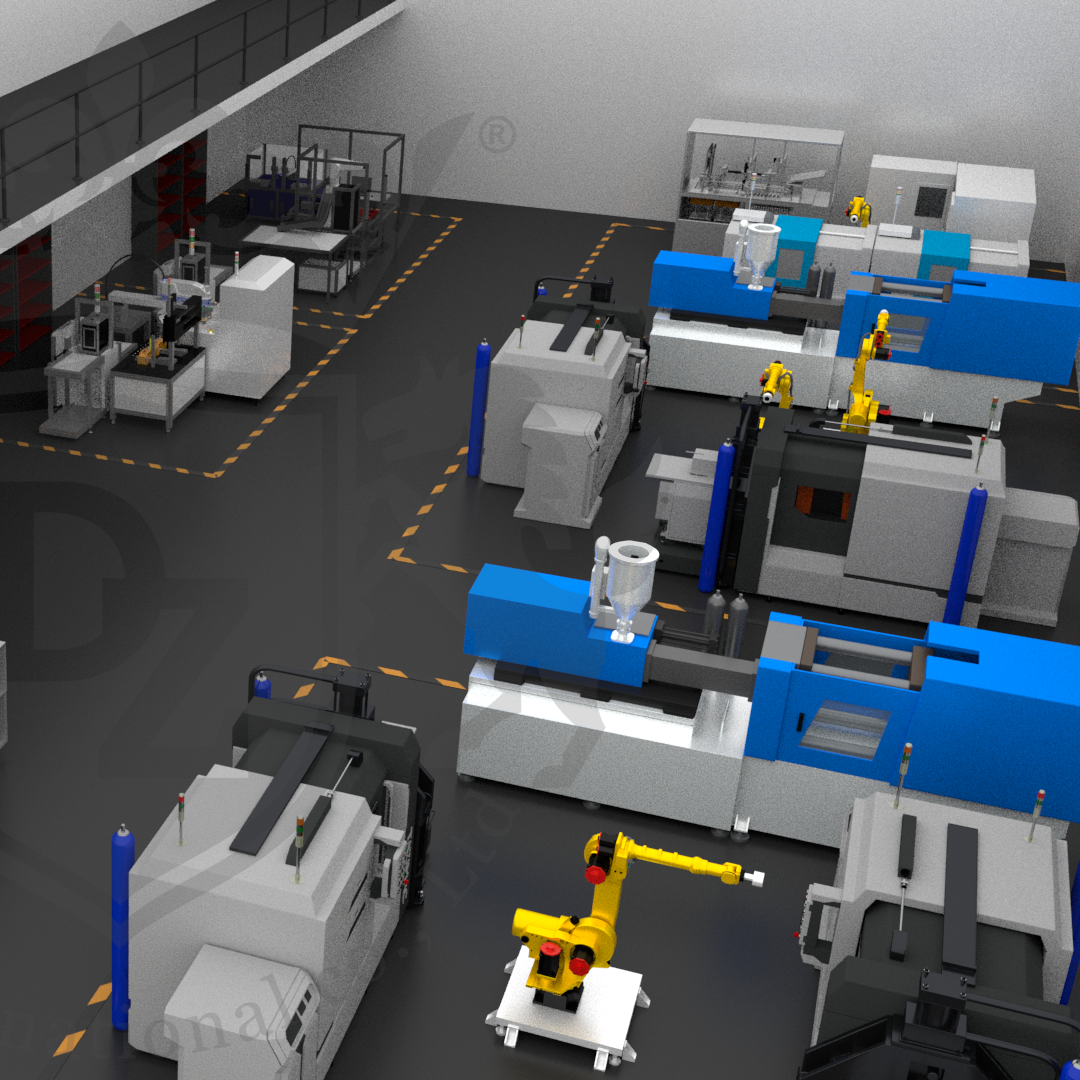

In the field of robots, array picking, stacking, unstacking, random picking, and conveyor belt tracking are common and complex applications. Traditional design methods are usually time-consuming and labor-intensive. However, our company has experienced all of the above functions in independent development; we can carry out project design, and we also have relevant know-how to provide.

MORE

Whether it is in the machining process industry or in the field of quality management, mechanical vision plays a key role. Our company is good at mechanical vision. Whether it is defect detection, image measurement, or other functional requirements, the company has design relevant and technical experience. In recent years, it has also developed its own visual image processing system (DAVS), which makes the design and development process faster, saves more time and money.

The advantages of this system are as follows:

⭐Multiple image processing functions, inspection, and measurement

⭐Graphic design, a quicker parameter adjustment interface that is suitable for various image observation and analysis, and a quicker way to obtain the desired results.

DZ International’s main technology is the integration of 3D visual recognition systems. Currently, the technologies and algorithms are all self-developed by the company, which can achieve full autonomy in technology. In recent years, it has also invested in the development of the robot application editing system RAE and the visual image processing system DAVS, which integrated years of project experience and technology into the systems. This system has a graphical design that breaks the stereotype of the high threshold and high technology of the robots, allowing users to learn to move the robots in just 5 minutes and the whole system in 1.5 hours, significantly reducing the time and cost of function development. For more complex robot control, within the framework of RAE, we introduce the machine image vision system (DAVS) that our company is an expert in. The system provides users with various measurement and inspection functions, including defect detection, image alignment, work piece measurement, etc.; it can also be combined with RAE to become the eyes of the robots for unstacking, positioning, handling, and visual-assisted processing. The company has also developed the RAE and DAVS systems through years of experience in the past, which implemented the simple use of robots for everyone and also solved most small and medium-sized business owner problems, such as "the shortage of talented employees and the need to train specialists to maintain machines."

Primarily research and develop 2D and 3D visual recognition robot control, visual measurement, and detection-related software and hardware equipment integration, and assist customers in handling equipment automation.

Published a 3D automatic dynamic online glue spraying system (3D tracking) and a 3D bulk material automatic picking system (3D picking), so that robot automation is no longer limited to 2D planes and achieves online 3D automation.

In 2016, the CM-IDL4 system was released, which combines automatic control with system management to effectively realize the concepts of Industry 4.0 such as manufacturing processes, production management, and mechanical automation. Through the collection of big data, it controls production progress, quality, yield, and machine status, strengthens material management, and controls all factory conditions in real-time.

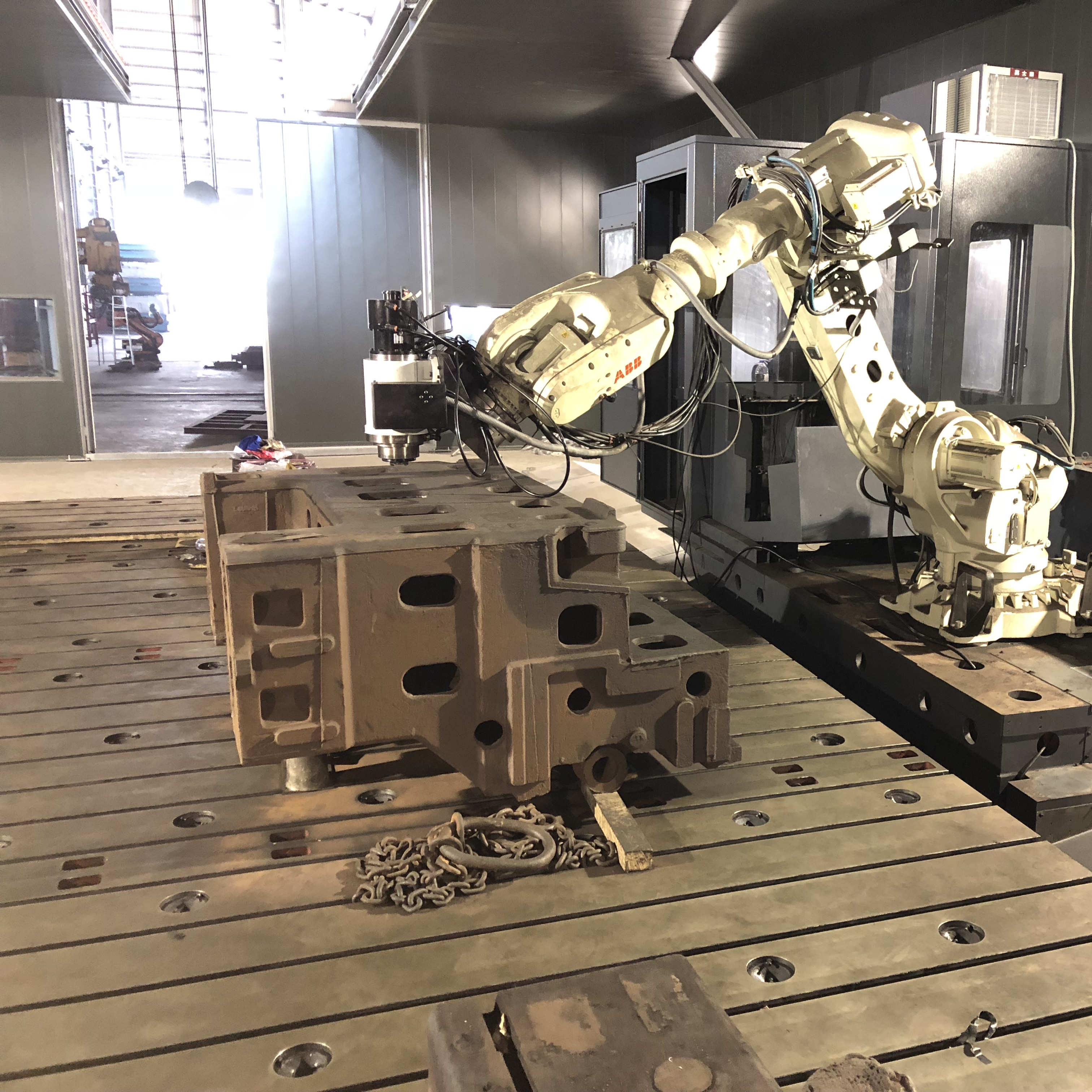

The first to break through the traditional way of using CAD/CAM to plan the path of the robots was being able to apply the technology to the processes of grinding, welding, cutting, polishing, and other processing of the robots.

With years of experience piled up in the control and integration of robots in DZ Internationals, the functional elements required by the robots are completely fused into the RAE system. RAE's humanized design helps you learn to move and operate the robots in 5 minutes and the whole system in 1.5 hours. Completely tearing down the walls of high-tech robots and allowing everyone to easily get started with the robots, making the production line development process faster.

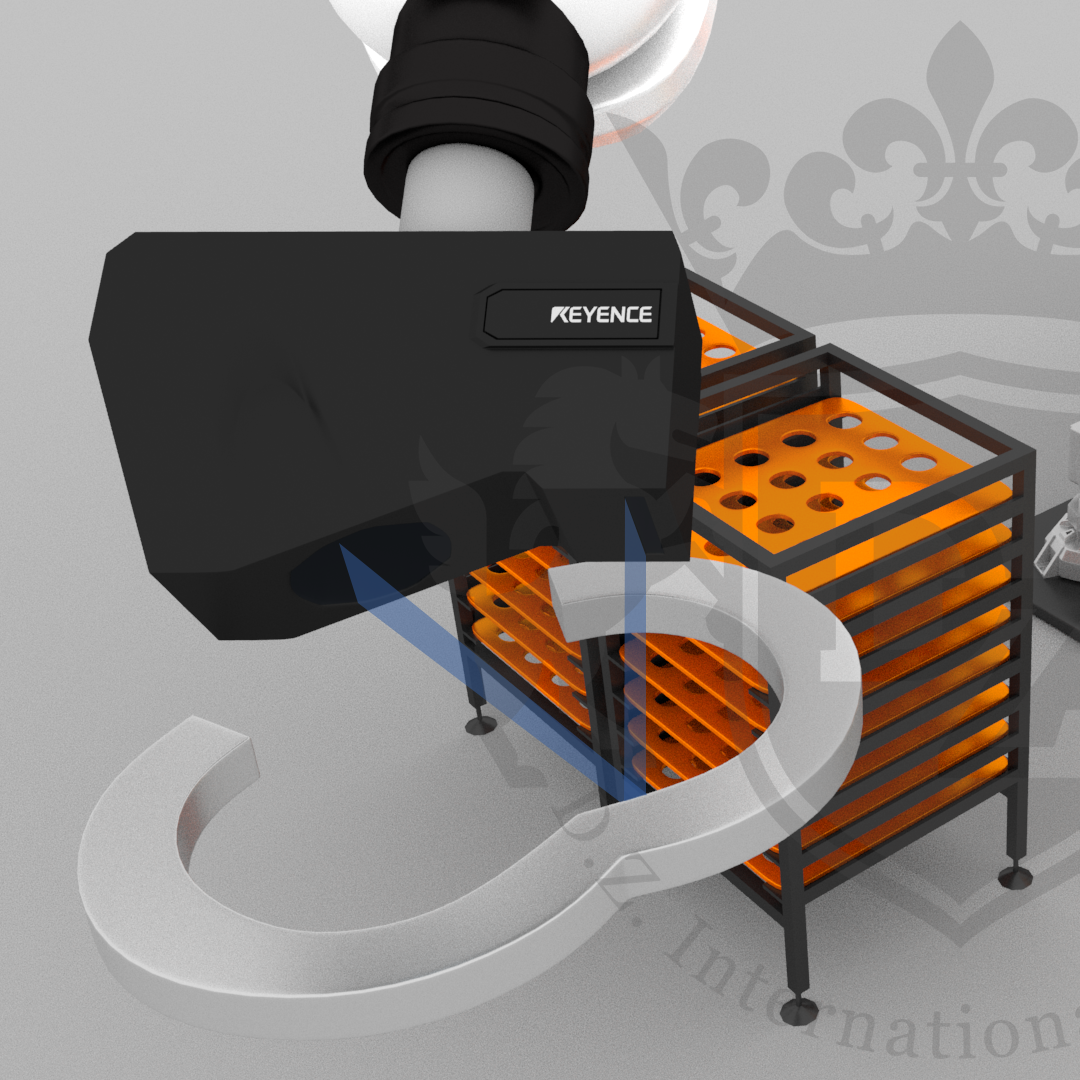

Under the RAE arm architecture platform, D.Z. International further imports DAVS, the machine with a better vision system. It provides users with applications to perform various dimension measurements and defect detection and includes various AOI applications such as defect inspection, presence inspection, image alignment, and workpiece measurement. Furthermore, it can be combined with RAE to become the eyes of the robots to meet the needs of unstacking, positioning, handling, visual-aided processing, etc.

Continuing the CM-IDL4 system in 2016, DZ Internationals developed a new Factory Boss for manufacturing management. Not AI, but BI! Import Business Intelligence (BI) smart thinking guidance and decision-making suggestion algorithms. Data collection, analysis, judgment, and decision-making will change with different factors, integrating production management, procurement, ordering processes, and production line information together reduces the time-consuming decision-making caused by variable factors in collecting relevant data and judgments.

Publishing the 3D grinding coordinate origin positioning technology of robot manipulators combined with line lasers. Using the Keyence LJ-X8000 series of high-speed and high-precision scanning, we assist in converting the point group data into STL files, which are combined with the DZ international development system for quicker scanning and reverse engineering.

The standard RAE, RAE stacking, and display operation versions have been launched. Each version has its own advantages, and every version can be selected according to customer needs, allowing users to use the RAE system more conveniently and quickly.

We also continue to add the KAWASAKI-KEBA controller and COMAU arms so that the robots can be used globally.

Publishing the 3D grinding coordinate origin positioning technology of robot manipulators combined with line lasers. Using the Keyence LJ-X8000 series of high-speed and high-precision scanning, we assist in converting the point group data into STL files, which are combined with the DZ international development system for quicker scanning and reverse engineering.